In response to disruptive global events such as geopolitical tensions and continuously changing shipping guidelines, enterprises are increasingly prioritizing making their supply chains resilient and agile. There is a significant emphasis on digitalization, integrating AI, IoT, and analytics technologies to improve network transparency, efficiency, and security. Sustainability has also become crucial, as businesses aim to minimize environmental impact and uphold ethical practices in their supply chains. These changes not only address regulatory pressures but also align with consumer expectations for responsible business practices. Overall, these shifts are transforming supply chains into more dynamic, interconnected, and accountable systems capable of meeting the complex demands of the modern global market.

There’s a growing trend toward creating collaborative ecosystems that include suppliers, partners, and even competitors. This approach leverages shared technology platforms and data insights to collectively drive efficiencies and innovate supply chain solutions.

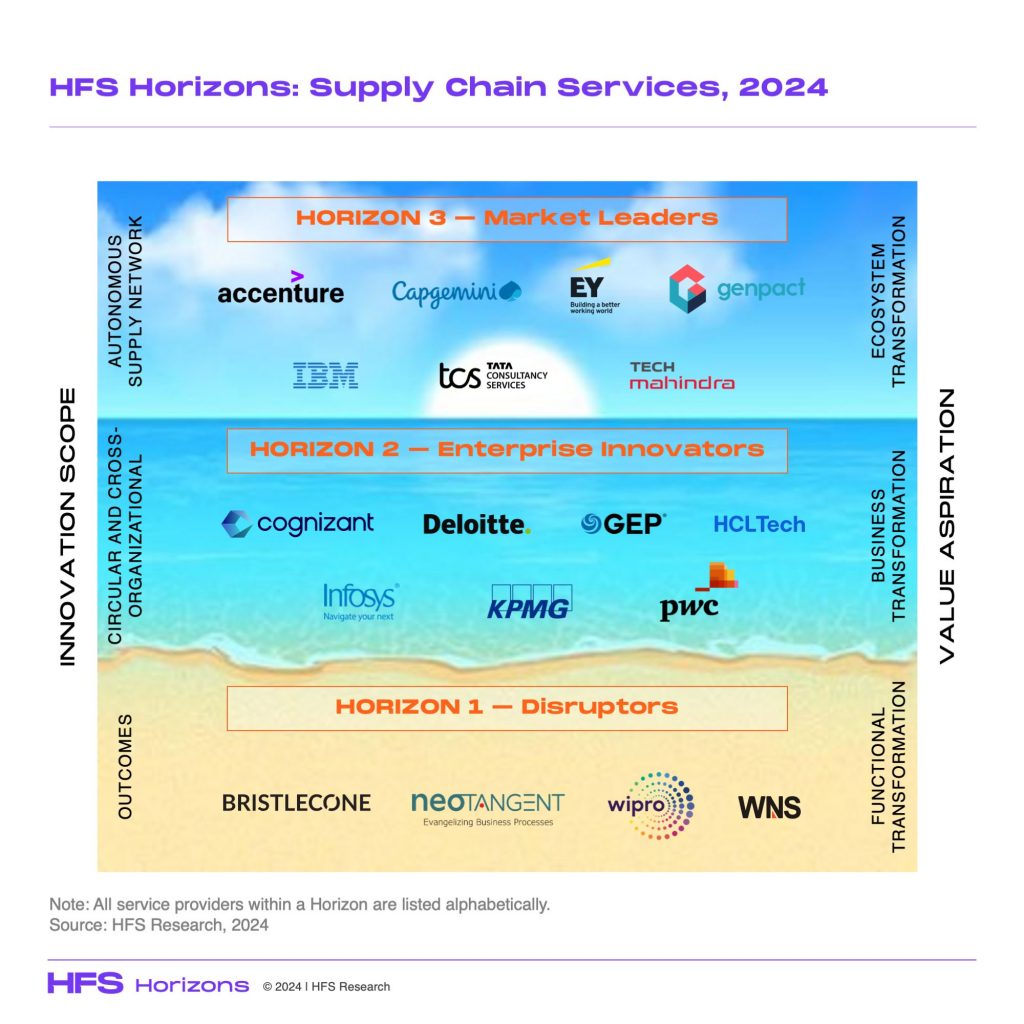

In the HFS Horizons: Supply Chain Services 2024 study, 18 supply chain services providers are analyzed and profiled. Seven of these providers are identified as leaders in Horizon 3, focusing on ecosystem collaboration. Seven are identified as innovators in Horizon 2, excelling in cross-functional alignment, and four are identified as disruptors, primarily working on function-level transformation.

Exhibit 1: 68% of upcoming supply chain investments in the next 2 years will be in Horizon 3

New service offerings coming into the fray

- Generative AI integration: There’s a significant push toward integrating GenAI across various facets of supply chain management, from planning and logistics to customer interaction and compliance. This technology is expected to enhance automation, improve decision-making, and create more dynamic and responsive supply chain systems.

- Sustainability services: Providers are increasingly offering services to achieve sustainability goals, such as carbon footprint reduction, lifecycle assessments, and sustainable sourcing strategies. These services are crucial for companies aiming to meet regulatory requirements and consumer demands.

- Digital twins and advanced analytics: The use of digital twin technologies and advanced analytics is being expanded to offer more detailed insights into operations, enabling predictive maintenance, and optimizing supply chain resilience.

New buying patterns are surfacing

- Shift toward subscription and as-a-service models: There’s a noticeable trend toward subscription-based and as-a-service purchasing models. These models provide flexibility, reduce upfront costs, and align with the increasing preference for OpEx vs. CapEx expenditures in corporate budgeting.

- Increased demand for customized solutions: Enterprises are looking for solutions they can tailor to their specific needs, reflecting a move away from one-size-fits-all offerings. This customization is particularly prevalent in areas such as AI implementations and data analytics services.

New scope of work on the table

- Global expansion: Organizations are increasingly designing supply chain solutions to support global operations, with a focus on integrating cross-border supply chains and managing international compliance and logistics challenges.

- Focus on resilience and agility: Services are being developed to enhance the resilience and agility of supply chains, enabling enterprises to respond more swiftly to market changes and disruptions. This includes tools for better risk management and dynamic rerouting of logistics in response to external shocks.

New operating models being adopted

- Collaboration across sectors: There’s an increasing emphasis on collaboration across different sectors and industries to optimize supply chain operations. This involves partnerships with tech companies, logistics firms, and even competitors to pool resources and capabilities.

- Leveraging big data and IoT: The scale of supply chain operations is expanding with the integration of IoT and big data. These technologies enable teams to handle vast amounts of data across extensive networks, improving real-time decision-making and operational efficiency.

The Bottom Line: The shift toward deeper digital integration and an evolved operating model is transforming human-dependent supply chains into low-touch collaborative supply networks.

HFS subscribers can download the report here.

Posted in : Artificial Intelligence, GenAI, HFS Horizons, internet-of-things, Supply Chain, supply-chain-management, sustainability